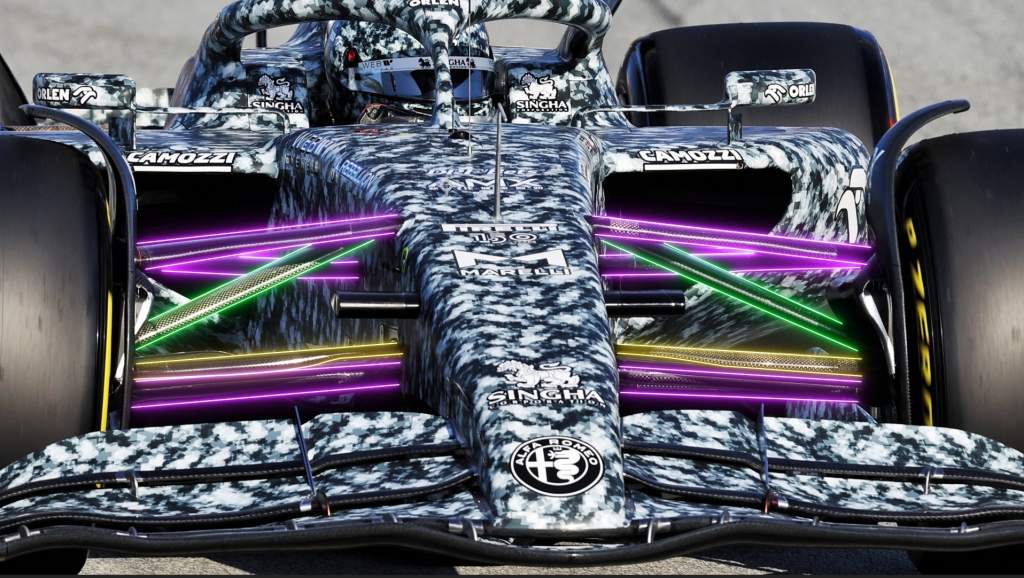

We did see a little of the new Alfa Romeo C43 from its Fiorano shakedown last week, but the first day of pre-season testing is the first time we’ve been able to take a clear look at the car.

Although the camouflage livery makes it tricky to see some details, which is the whole point of it, there’s still plenty to see on this new car.

It’s important for Alfa Romeo to make progress with this car. In recent years, it has struggled so given the statement its made by splashing out on signing Valtteri Bottas it needs to have the pace and the operational sharpness to show it can be more than a lower-part-of-the-grid runner.

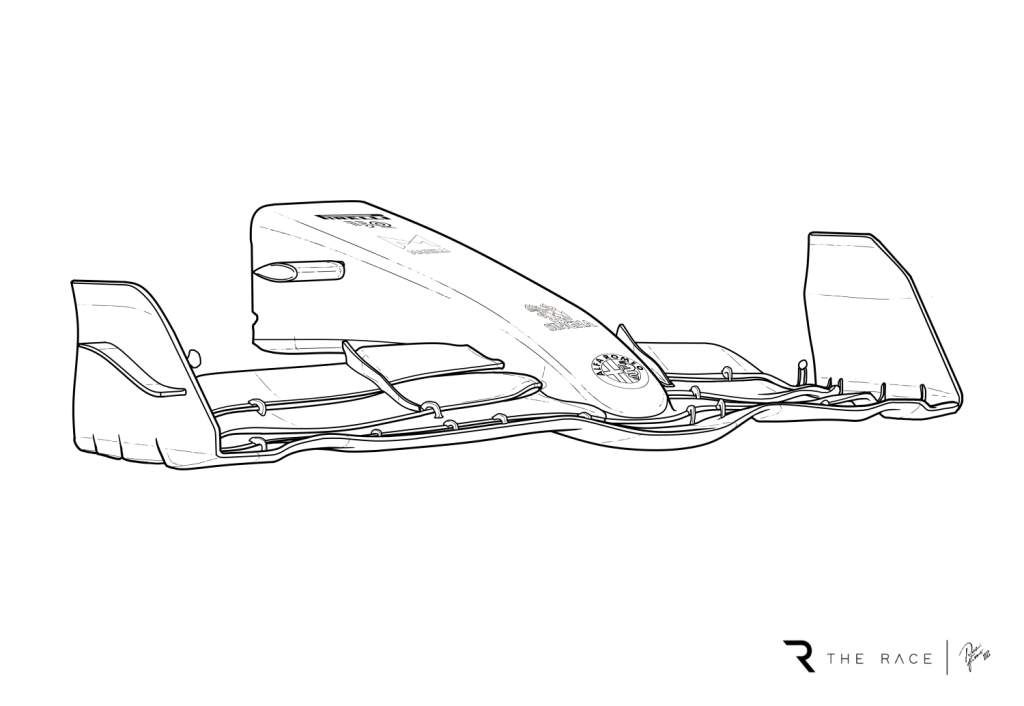

NOSE/FRONT WING

The forward element has a slot gap separating it from the second element, as on the Aston Martin and McLaren. This helps with the airflow to the underside of the nose, but on this car the nose doesn’t seem to be as high as on some others so Alfa should have less problem keeping the airflow attached to the nose’s undersurface.

The front flaps are reasonably evenly loaded across their span, with the third and fourth flaps fixed to the nose.

The outboard section of that looks like it is adjustable more or less to where it joins the endplates. Over the last few seasons, Alfa Romeo has run this outer section of the flaps at very low angles, lower than anyone else, so should have a good grasp of what it is trying to achieve with this relatively similar design

The endplates are more or less to the letter of the regulations, and they have the common ski ramp on the outer surface.

FRONT SUSPENSION

This is where it all gets a bit different. Alfa Romeo has a normal top and bottom wishbone solution with a pushrod operating the inner suspension components.

It is difficult to see where the rear leg of the lower wishbone fixes into the chassis, but it doesn’t look like it is in line or higher than the forward leg. If it is lower, this will allow the front of the car to dive under braking.

The top wishbone is a completely different story. The wishbone outboard end is very high in the 18-inch wheel and the inboard end of the forward leg is mounted even higher again.

The rear leg inboard end is mounted much lower. I don’t think I have ever seen as much of a height difference between the mounting of the same wishbone legs.

This will induce anti-dive under braking supporting the front of the car, depending on the actual longitudinal movement of the outer wishbone ends when the suspension goes into compression. I would expect this setup to increase the caster, but there is probably a lot more to it than that.

Within the regulations for 2022, the front ride height change with steering lock has been limited. But that’s doesn’t prevent you achieving a ride height change with increased caster.

In the past, the pushrod geometry to the front upright meant that with more steering lock the front of the car was lowered to give more front grip in slow corners.

Perhaps this caster increasing with speed means that the front ride height also increases, or in effect reduces less with speed, meaning the car can be as low as possible for slow and medium speed corners and rise for the faster corners.

FRONT BRAKE DUCT

These are very similar to what we have already seen from other cars where it runs into the mudguard area.

UNDERFLOOR LEADING EDGE

It’s very difficult to see with the camouflage paint work scheme, but the outer splitter/bargeboard area doesn’t look to be quite as large as it can be. But for a real assessment a closer look is needed.

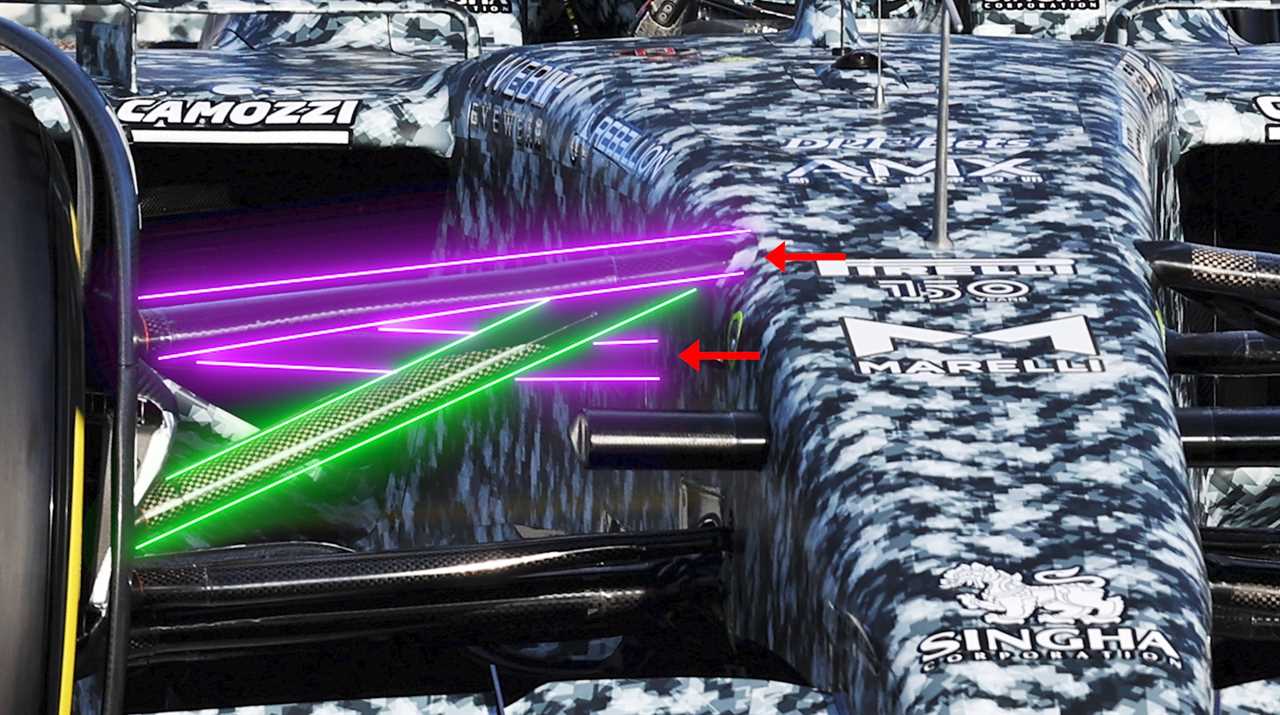

SIDEPODS

This area is a step in the direction that Aston Martin has come up with.

Alfa has the main sidepod volume in the upper section and a reasonable undercut running from front to rear of the sidepod before it blends into the top surface of the floor.

The sidepod itself not as dramatic as on the Aston Martin, but it will connect up the front to the rear of the car and allow the coke bottle area to improve the performance of the front of the car. I always say you can’t push the the airflow around the car, you have to pull it and this undercut allows that to happen.

Where most teams have a curved upwards section on the outer edge of the floor to help pull some of the airflow out of the underfloor, Alfa has doubled this up with a separate turning vane that is mounted at the rear but not at the front.

It will be interesting to see if this component gets questioned by the FIA. If not, it does open the door for a variety of turning vanes that are not integrated into the bodywork as clearly as the rules intended

AIRBOX INTAKE

Alfa has gone with aa similar central rollover bar solution to the one it ran a few years ago.

The actual intake opening is quite small, it also uses the Ferrari power unit so this is no real surprise as the other two Ferrari PU users also have small area inlets.

I’m sure this means that the cooling requirement has either been reduced or repackaged lower in the sidepod area.

However, as I said above, on the Alfa Romeo sidepods are quite different from the Ferrari package.

RADIATOR EXIT

There appear to be some louvres on the top of the sidepods and also on the engine cover just where it runs into the central fin.

It’s difficult to see, but with the rear of the sidepods sweeping in as quickly and as early as it does, there will not be much cooling area at the rear of the pods.

Obviously, there will be a gap from the body profile to the mechanical components – the regulations have tried to limit the size of these openings where they go around the suspension components but there is no limit on the opening where they leave room to the gearbox.

COKE BOTTLE AREA

This is fairly abrupt with no real inner body work.

Alfa Romeo is maximizing the size of the coke bottle by simply allowing the sides of the gearbox to be the inner coke bottle surface.

As long as the outer gearbox housing surface is sympathetic to this airflow, this is not a bad idea. However, achieving this might just be a compromise to the housing’s structure.

REAR SUSPENSION

Like McLaren and Red Bull, Alfa Romeo has deviated from the norm in going to a pushrod rear suspension.

I’m a bit surprised by this as Alfa Romeo uses the Ferrari gearbox cluster. But in order to have freedom in suspension geometry, the outer gearbox casing is of its own design.

This is likely to have been done for packaging reasons. McLaren went for the pushrod configuration for packaging reasons because the shorter wheelbase meant a slightly shorter gearbox – but others have opted for a different compromise.

REAR WING

Other than the size of the spoon section, all the wings we have seen are designed as expected to comply with the new regulations. I’m sure over time this area will take on a new look but for now everyone is happy to get ‘version one’ on the car and see what others have done and where that might lead them.

Alfa Romeo’s version is twin pillar mounted with the DRS actuator mounted on the upper surface on the car centreline.

BEAM WING

As per the regulations, this is a twin-element component with quite an aggressive angle on the rear flap.

The beam wing will be optimized to connect the airflow coming out of the diffuser to the airflow on the underside of the upper wing. If all there of these components work together as one, they are much more powerful than if they work individually.

DIFFUSER

It’s difficult to see clearly given such a dark opening, but I’m pretty sure it will maximize the open area allowable in the regulations.

CONCLUSION

This car incorporates various solutions that are being used on other cars and shows the team has gone its own way with the combination of those it has selected.

It’s nice to see this as we could call all these cars ‘blind versions’ in that they have been designed with a team’s own ingenuity and not steered by what others have been up to.

The big question is, what of those solutions are the correct ones? The answer to that is that we are still a long way down the road from getting any understanding of what the development priorities are going to be.